Big Brand Core Is Stable And Reliable

Imported Generator Set Is Used, With An Engine Power Of 52KW And Continuous Supply Of 380V Electricity.

Imported Generator Set Is Used, With An Engine Power Of 52KW And Continuous Supply Of 380V Electricity.

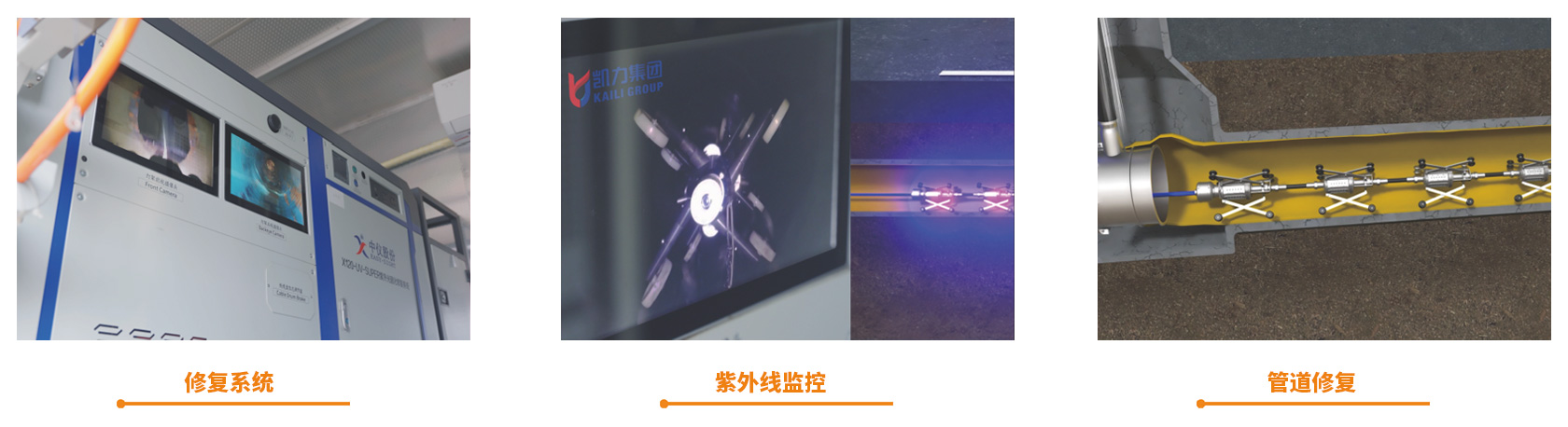

The UV Repair System Consists Of A Mobile Control System, Transmission Cable, UV Lamp Holder, High-definition Lens, And Auxiliary Tools. Adopting Integrated Design, High Integration, Small Size, And Light Weight. An External Generator Can Work. The Mobile Control System Can Be Separated From The Vehicle And Operated On Narrow Streets.

UV Lamp Holder, With High Luminous Efficiency, Is More Than Three Times That Of Traditional Lamps. The Cold Light Source Has No Thermal Radiation, No Infrared Radiation, No Harmful Gas Generation, Meets ROHS Standards, No Explosion Or Splashing, And Is Safer And More Environmentally Friendly. Adopting LED Dot Matrix Light Source, Modular Integrated Fixation, No Disassembly, Long Service Life, Low Power Consumption, Fast And Safe.

Adopting An Intelligent Operating System From A Leading Domestic Non Excavation Technology Equipment Manufacturer, The Repair Process Is Visible, With Dual High-definition Videos For Front And Rear Viewing, Automatic Constant Pressure, Simple Operation, Easy To Learn And Use. Adopting A Movable Control Cabinet, Highly Integrated, Built-in Fan, Compact Size, Lightweight And Easy To Carry, The Overall Volume And Weight Of The Machine Are About 1/2 To 1/3 Of Traditional Equipment.

The UV Lining Repair Material Mainly Consists Of Five Parts: Protective Film, Outer Film, Fiberglass Cloth, Inner Film, And Pre-set Rope. After Dragging The Hose Material From The Inspection Well Into The Pipeline To Be Repaired, It Is Expanded With High-pressure Air And Tightly Adhered To The Inner Wall Of The Pipeline To Be Repaired. Then, LED Light Curing Equipment Is Used For Curing, And The Fiberglass Pipe Material Is Then Covered On The Drainage Pipeline To Provide Sealing And Reinforcement.

No Excavation Is Required, And The Entire Drainage Pipeline Can Be Repaired Using Inspection Wells, Which Can Repair Structural Defects Such As Rupture, Misalignment, Disconnection, Tree Root Invasion, And Leakage In The Drainage Pipeline. The Inner Lining Layer Is Smooth And Continuous, With A Thickness Of 3-15mm, Which Reduces The Surface Roughness Of The Pipeline And Improves Its Conveying Capacity. The Inner Lining Material Has Good Toughness And High Strength, And Is Compatible With Composite Resin Impregnation. After Curing, The Bending Die Weight Of The Inner Lining Layer Can Reach 12000MPa. The Inner Lining Layer Is Tightly Adhered To The Original Pipeline To Isolate The Corrosive Environment And Play A Role In Leak Prevention.