【 Maintenance 】 Treatment Methods And Precautions For Sprinkler Pumps

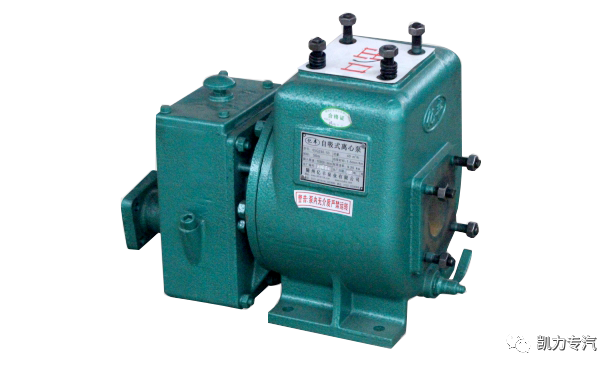

Working Principle And Performance Characteristics Of Sprinkler Pump

1 Working Principle

The Sprinkler Pump Is Also A Centrifugal Pump. When The Centrifugal Pump Is Working, The Liquid Fills The Pump Casing, And The Impeller Rotates At High Speed. The Liquid Generates High Speed Under The Action Of Centrifugal Force. The High-speed Liquid Passes Through The Gradually Expanding Pump Casing Channel, And The Dynamic Pressure Head Is Transformed Into A Static Pressure Head.

2 Performance Characteristics

● Efficient And Energy-saving

The Pump Has An Efficient Hydraulic Line And High Working Efficiency.

Easy Installation And Maintenance: With A Vertical Pipeline Structure, The Inlet And Outlet Of The Pump Can Be Installed At Any Position And Direction In The Pipeline Like A Valve, Making Installation And Maintenance Extremely Convenient.

● Smooth, Safe And Reliable Operation

The Motor Shaft And Water Pump Shaft Are Coaxial And Directly Connected, With High Concentricity, Ensuring Smooth And Safe Operation.

Stainless Steel Shaft Sleeve

The Mechanical Seal Position Of The Shaft Is Relatively Susceptible To Corrosion, And Once The Shaft Of A Direct Coupled Pump Is Corroded, It Can Easily Cause Mechanical Seal Failure. The Use Of Embedded Stainless Steel Shaft Sleeves Avoids Corrosion, Improves Shaft Life, And Reduces Operating And Maintenance Costs.

● Bearings

The Lower Shaft Extension End Bearing Of The Motor Equipped With The Pump Adopts A Closed Bearing, Which Eliminates The Maintenance Of The Motor Bearing During Normal Use.

● Machine Seal

The Mechanical Seal Base Is Generally Made Of Rubber Bellows Structure, Which Changes The Traditional Axial Seal Of The Mechanical Seal From An O-ring Line Seal To A Two-way Rubber Seal, Improving The Sealing Effect In Clear Water Medium.

How To Deal With A Sprinkler Pump Without Pressure?

NO.1

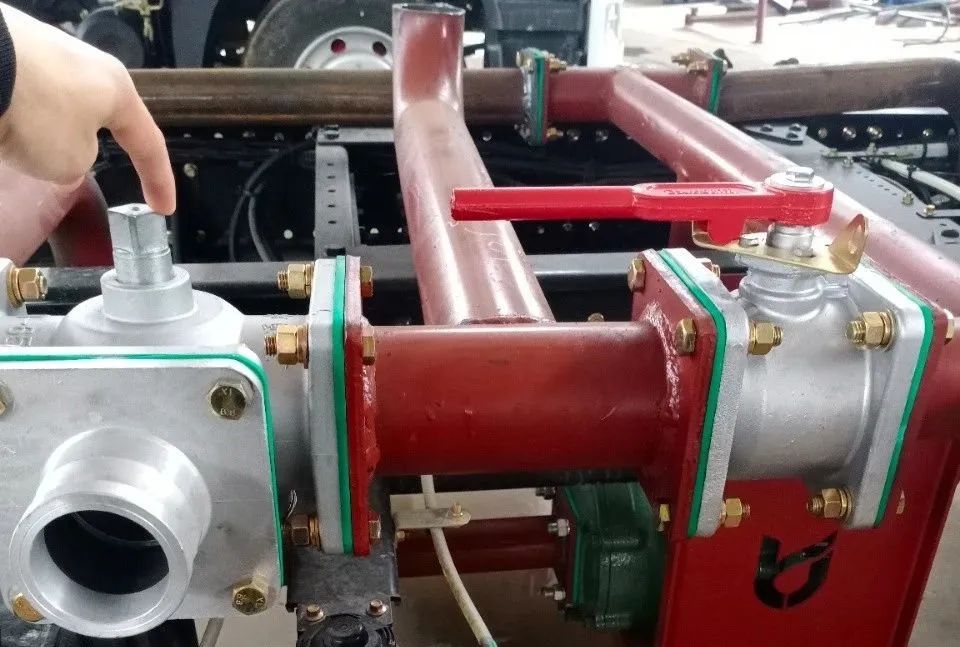

The Sealing Of The Sprinkler Pipeline Is Not Tight. You Can Check The Rubber Gasket, Adjust The Thickness Of The Sealing Gasket, And Tighten The Joint Screws.

NO.2

Check The Water Pump And Pipeline. If There Is No Leakage, Easily Rotate The Water Pump By Hand. When The Pump Works Without Noise, It Can Basically Eliminate The Problem With The Water Pump Itself.

NO.3

Check The Water Intake, And If There Is Insufficient Water Intake, Add More Water Intake. When There Is Insufficient Water Intake, Not Only Can't The Water Be Pumped Out, But The Water Seal Of The Pump Will Also Immediately Burn Out. Water Seal Damage And Related Issues Caused By Water Seal Damage Are Not Within The Scope Of The Three Guarantees.

NO.4

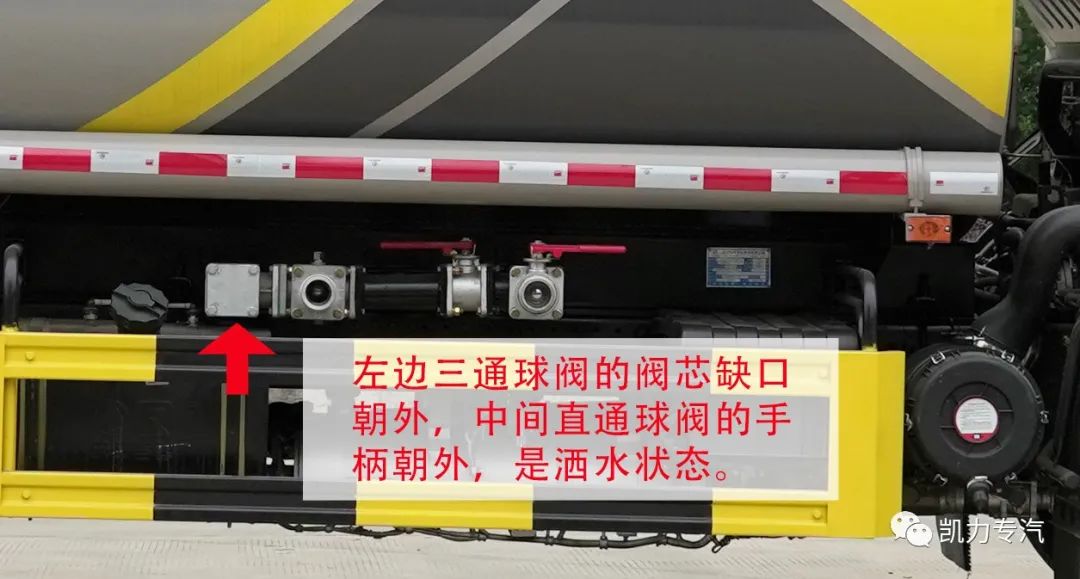

Check The Opening Status Of The Ball Valve On The Pipeline And Whether The Filter Screen Is Clean. The Filter (circled In Red) Can Be Disassembled And Installed In Reverse. The Filter Core Is Covered With A Layer Of Fine Pore Filter, Which Needs To Be Removed. If The Filter Core Is Installed Upside Down And Water Is Sprayed, There Will Be No Pressure And The Pumping Speed Will Be Relatively Slow.

Treatment Method For High Noise And Vibration Of Sprinkler Pump

NO.1

Unstable Footing, Treatment Method: Reinforcement.

NO.2

Cavitation Phenomenon, Treatment Method: Adjust The Working Conditions.

NO.3

The Bearing Is Severely Worn, And The Solution Is To Replace It With A New Bearing.

NO.4

If The Flow Channel Inside The Pump Is Blocked Or Stuck, The Solution Is To Correct Or Replace It.

NO.5

There Are Debris In The Pump Or Inlet Pipeline. Solution: Remove The Debris.

NO.6

The Main Shafts Of The Pump Or Power Machine Are Different, And The Solution Is To Adjust The Coaxiality.

Precautions

NO.1

During Each Watering Operation, If There Is Not Much Water Left In The Tank, The Power Take-off Must Be Immediately Turned Off.

NO.2

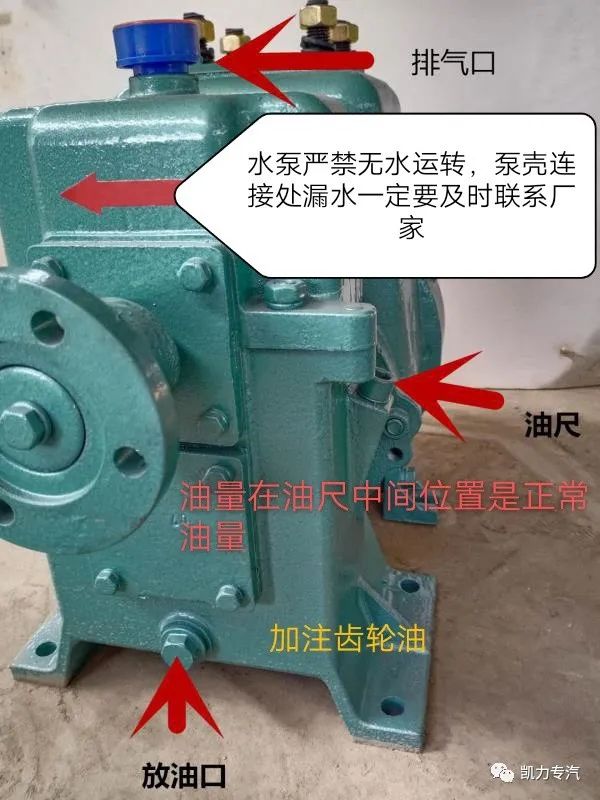

After The Water Inside The Pump Is Drained In Winter, It Must Be Filled With Water Before Being Used Again. Otherwise, The Water Seal Will Quickly Burn Out.

NO.3

The Gear Oil Of The Water Pump Must Be Replaced After Three Months Of Use, And The Gear Oil Should Be Checked And Replaced Regularly In The Later Stage.

NO.4

There Are Two Reasons For Fuel Injection At The Exhaust Port Of The Water Pump Gearbox. The First Is That The Throttle Is Applied Too Much During Operation. The Second Is Caused By Water Entering The Gearbox After The Water Seal Is Burned Out.