【 Maintenance 】 Three Common Faults Of Sprinkler Trucks During Use

Fault One

The Sprinkler Truck Has A Slow Speed Or Cannot Pump Or Discharge Water At All.

● Exclusion Method:

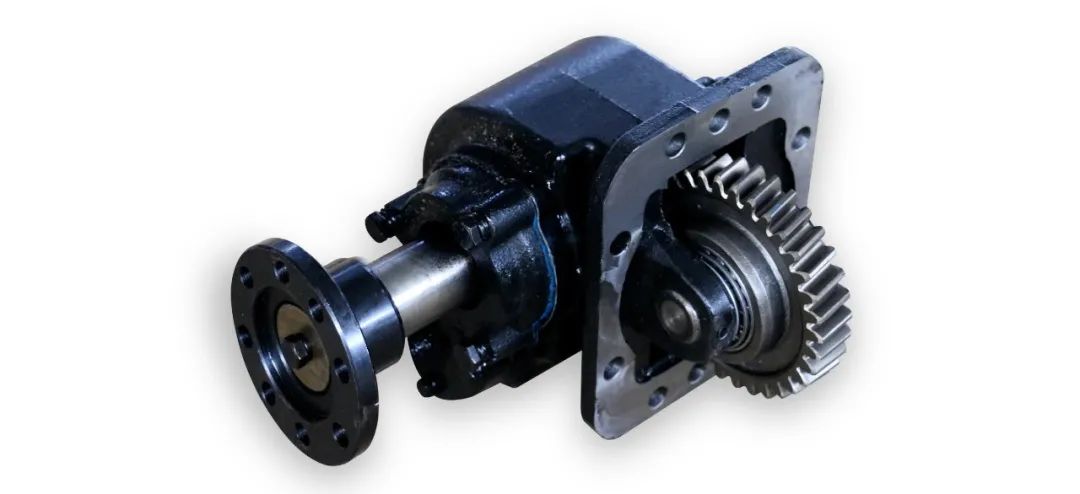

Firstly, Check Whether The Connection And Gear Fit Between The Power Take-off, Transmission Shaft, And Sprinkler Pump Are Tight And Effective, And Whether There Is Any Looseness. If This Situation Occurs, It Should Be Tightened In A Timely Manner;

The Second Is To Check Whether There Is Any Air Or Water Leakage In The Connection Between The Inlet Pipes, And To Deal With Such Situations;

The Third Is To Check Whether The Inlet And Pipeline Filter Screens Are Blocked, And If So, Remove Them. The Sprinkler Truck Manufacturer Suggests Installing A Filter Screen At The Inlet And Regularly Removing The Pipeline Filter Screen;

Fourthly, Check Whether There Is Water Intake In The Sprinkler Pump. The Sprinkler Truck Manufacturer Strictly Prohibits Starting Vehicles Without Water Intake In The Sprinkler Pump;

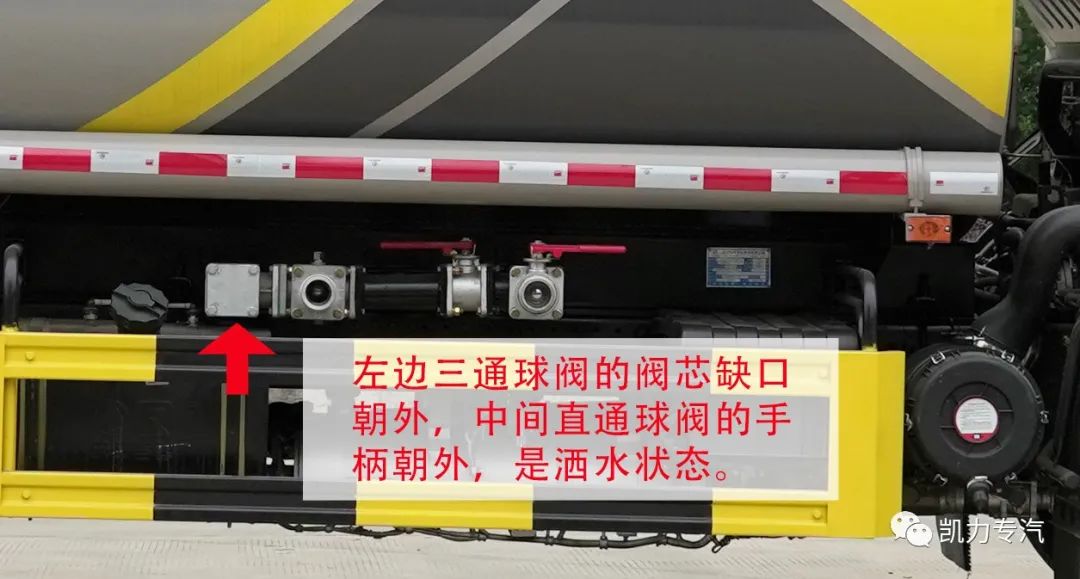

The Fifth Step Is To Check Whether The Position Of The Inlet Valve Is Correct. Incorrect Valve Switch Position Can Cause Water To Not Be Pumped Up Or Discharged. Please Follow The Instructions For Operation. The Above Situations Can Cause Slow Pumping Or Inability To Pump Incoming Water, And Should Be Eliminated As Soon As Possible.

Fault 2

The Sprinkler Pump Of The Sprinkler Truck Often Freezes And Cracks Or The Impeller Of The Sprinkler Pump Is Damaged.

● Exclusion Method:

The Main Reason Why The Sprinkler Pump Of The Sprinkler Truck Often Freezes And Cracks Is Due To The Failure To Discharge The Water In The Sprinkler Pump In A Timely Manner After Using Up The Sprinkler Truck In Cold Weather, Which Can Be Avoided As Long As One Pays Attention To It Regularly. There Are Two Reasons Why The Sprinkler Pump Impeller Of A Sprinkler Truck Is Damaged.

1. When Pumping Water, There Was No Water Intake In The Sprinkler Pump. The Sprinkler Pump Operated For A Long Time At High Temperature, Causing Damage To The Impeller;

2. If The Filter Screen Is Damaged And Not Replaced In A Timely Manner, Sand And Other Hard Particles Will Be Pumped Into The Water Pump, Causing Damage To The Impeller. This Type Of Situation Can Be Avoided By Paying Attention To It Regularly. Once The Impeller Is Damaged, It Should Be Replaced. The Sprinkler Truck Manufacturer Suggests That It Is Best To Replace The Sprinkler Pump.

Fault Three

The Sprinkler Truck's Sprinkler Gun Cannot Rotate.

● Exclusion Method:

The Inability Of The Sprinkler Cannon To Rotate Is Mainly Caused By The Rusting, Wear And Deformation Of The Cannon Disc. In This Case, The Cannon Disc Can Only Be Replaced. The Sprinkler Truck Manufacturer Recommends Regularly Adding Lubricating Oil.