Regarding Refueling, There Are Great Considerations For National VI Vehicles!

To Protect The Ecological Environment, We Adhere To The Concept That Green Mountains And Clear Waters Are As Valuable As Mountains Of Gold And Silver. We Respect, Conform To, And Protect Nature, And Uphold The Boundaries Of Natural Ecological Security. As A Result, The National VI Fuel Standards And National VI Automobile Emission Standards Have Emerged One After Another. Today, Kaige Will Introduce To You The Issue Of Refueling National VI Vehicles.

Why Is It Necessary To Use National VI Fuel

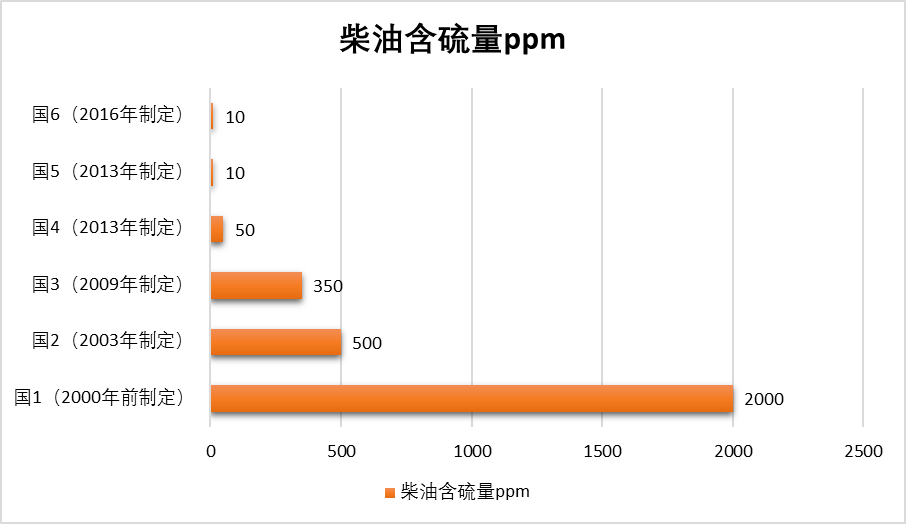

The Sulfur Content Index Of Diesel Directly Affects Emissions, And The National VI Diesel Standard Requires A Sulfur Content Of Less Than 10ppm. If The Fuel Is Not Up To Standard, It May Result In Emissions Not Meeting The Standard, Vehicle Speed And Torque Limits, Or Even Damage To The Vehicle's Electrical Components And Post-treatment, Directly Affecting The Use Of The Vehicle. Therefore, Using Qualified Fuel Is Very Important!

Excessive Sulfur Content In Diesel Can Cause Harm

Exceeding Emission Standards.

Accelerate The Deterioration Of Engine Oil, Corrode The Surface Of Internal Engine Components, And Accelerate Wear.

Causing Sulfur Poisoning In Components Such As DOC, DPF, And SCR Catalytic Bricks Of National VI Engines, Leading To A Series Of Problems Such As OBD Failures And Vehicle Speed And Torque Limits.

The Harm Of High Sulfur Fuel To DOC

In DOC, Precious Metals Are Used To Achieve Oxidation Catalysis. If Sulfur In Diesel Enters The Exhaust System After Combustion, The Formed Sulfates Cover The Surface Of Precious Metals And Deposit, Causing DOC To Lose Its Oxidation Catalysis. Therefore, It Leads To A Chain Reaction That Affects The Passive Regeneration Of DPF, As It Cannot Provide Active Regeneration High-temperature Heat To DPF Through Oxidation Reaction. DPF's Active Regeneration Is Not Smooth Due To Low Temperature, Gradually Deteriorating Blockage, And SCR Urea Crystallization Will Also Accelerate.

The Harm Of High Sulfur Fuel To DPF

Excessive Sulfur Compounds In Diesel Can Lead To A Shortened DPF Cleaning Range, As The Sediment Captured By DPF Is Usually Composed Of SOF (soluble Organic Matter), Combustible Carbon, Non Combustible Graphite Carbon, Decomposable Sulfur Compounds, And Non Decomposable Sulfur Compounds. At Normal Operating Temperatures Of Diesel Engines, Passive And Active Regeneration Of DPF Can Only Remove SOF And Combustible Carbon From Clogged DPF Deposits, And Are Powerless Against Non Combustible Graphite Carbon, Decomposable Sulfides, And Non Decomposable Sulfides. With The Extension Of Diesel Vehicle Mileage, The Sediment In DPF Gradually Becomes Mainly Composed Of Refractory Graphite Carbon, Decomposable Sulfides, And Non Decomposable Sulfides, Making It Increasingly Difficult For DPF To Clear Blockages Through Passive And Active Regeneration. Resulting In An Increase In The Frequency Of Active Regeneration Of Vehicles, Requiring Frequent Service Regeneration And Dust Removal Processing, While Also Frequently Experiencing OBD Alarms And Speed Limits.

Hazards Of High Sulfur Fuel To SCR System

Excessive Sulfur Content In Diesel Can Cause Ammonia, NH, Sulfur Dioxide, And Water From Urea Solution To Form A Very Viscous Sulfide At A Certain Exhaust Temperature. On The One Hand, It Will Adhere To A Large Number Of Carbon Smoke Particles, And On The Other Hand, It Will Deposit In The Gaps Of Catalyst Attachments. Under Catalytic Action, It Will Polymerize Into Gelatinous Carbon Deposits That Are Not Easily Decomposed. Mild Cases Can Lead To Poisoning And Failure Of The SCR Catalyst, A Decrease In Conversion Rate, Increased Fuel Consumption, Insufficient Power, And Excessive Nitrogen And Oxygen Emissions In Diesel Vehicles; Severe Cases May Lead To Catalyst Blockage, OBD Alarm, Torque Limit, And Speed Restriction. The Sulfide Formed By Ammonia, Sulfur Dioxide, And Water Has A Strong Corrosive Effect On The Copper Based Carrier Of SCR Catalysts. If Not Removed In Time, It Can Greatly Shorten The Service Life Of The Catalyst.

Previously, Some Cardholders Would Add A Cheaper "small Fuel" To Reduce Transportation Costs. However, After Switching To The National VI Model, Many Core Components Have Been Upgraded And Optimized. Once Damage Occurs, The Cost Of Repair In The Later Stage Is High In Terms Of Money And Time. Cardholders Must Choose Compliant Fuel To Ensure Efficient Operation Of The Vehicle And Maximize Profits.