Countdown To Relocation Of Smart Factory! Kaili Group Is About To Relocate To A New Factory And Expa

Kaili Automobile Group Is About To Relocate To A New Factory!

Embark On A Stunning Journey With The Starting Point Of 'Intelligent Drive, Specialized Automobile, New Future'!

New Industrial Chain Upgrade, New Factory Covers An Area Of 330000 Square Meters!

Equipped With Internationally Leading Production Lines, It Is A Leading Potential Stock In The Industry!

Ask

What Is Kaili Smart Factory?

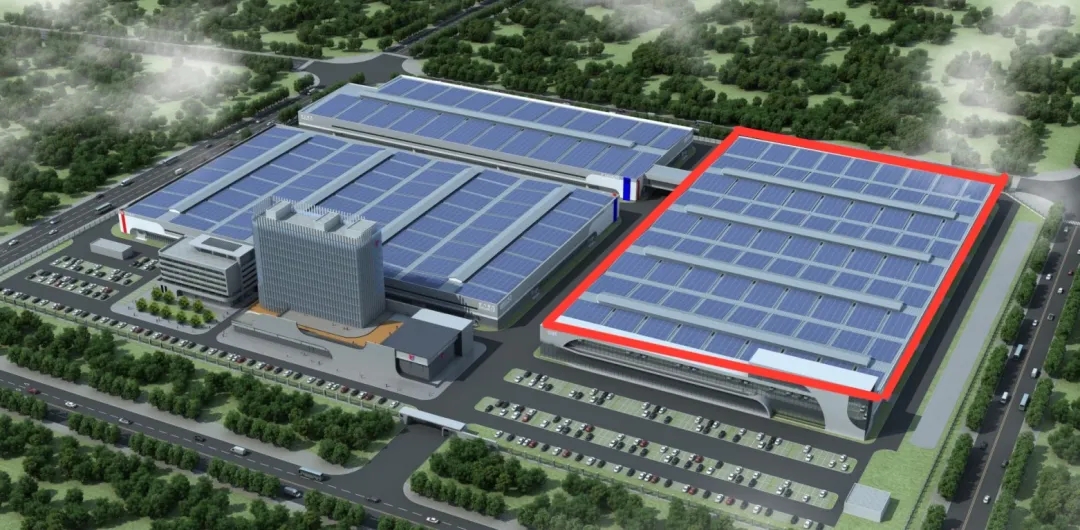

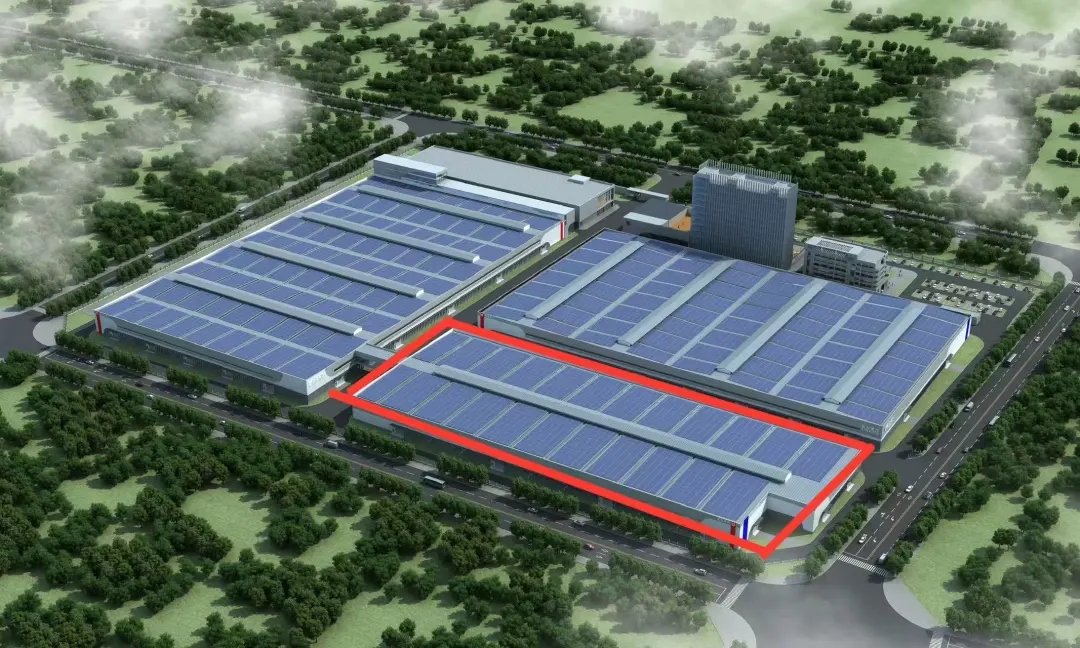

The Kaili Smart Factory Project Is Located In Zengdu District, Suizhou City, With A Planned Total Area Of 500 Acres. It Will Be Developed In Two Phases, With The First Phase Covering An Area Of 285 Acres And A Total Investment Of 650 Million Yuan. The Goal Is To Build A Benchmark Smart Factory Enterprise In The Field Of Specialized Automobiles In China, Including A New Production Command Center, Cutting Center, Automated Welding Machine Processing Center, Automated Coating Center, Automated Assembly Line Assembly Center, Chassis Dispatching Center, Logistics And Warehousing Center, Emergency Equipment Manufacturing Center, Special Vehicle Research And Development Center, Product Display Center, Integrated Media Incubation Base (referred To As "Ten Centers And One Base"), As Well As Comprehensive Office Buildings, Employee Dormitories, Cultural And Sports Activity Centers, Restaurants And Other Buildings. Supporting Facilities Include Greening And Water Supply And Drainage, Power Distribution, Fire Protection System, Environmental Protection Facilities, Photovoltaic Power Generation, Rainwater Collection, Etc. Utilize Public Auxiliary Facilities.

Ask

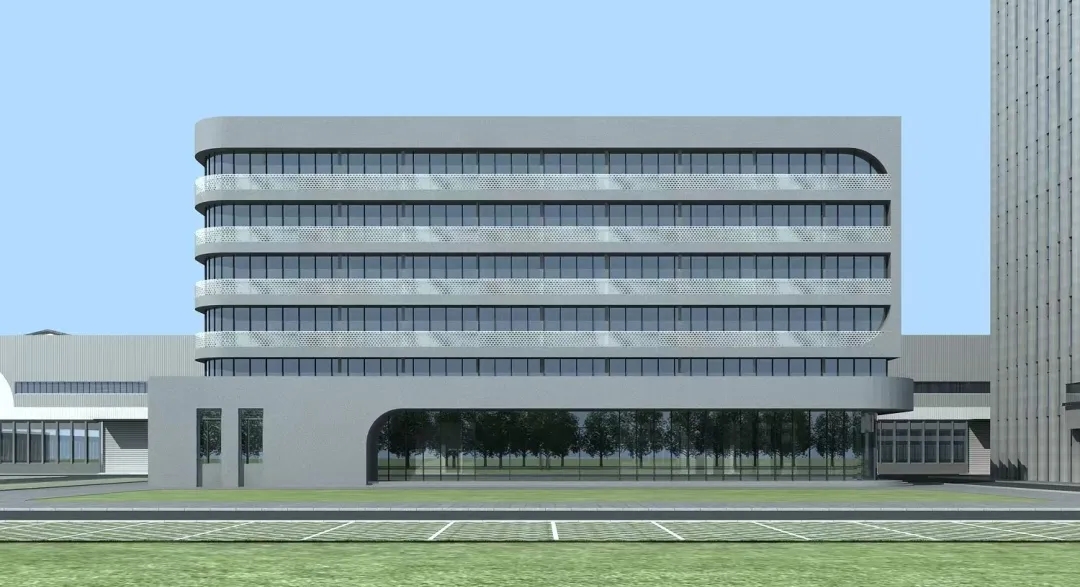

What Is The Smart Factory Research Building?

The Construction Area Of The Research Building Is 3880.80 Square Meters, With A Total Construction Area Of 21287.89 Square Meters. The Building Has A Total Of 12 Floors Above Ground And No Underground Space.

The Interior Of The Building Covers Multiple Important Functional Areas, Including The Enterprise Multimedia Exhibition Hall, Product Display Center, 400 National After-sales Service Center, Enterprise Integrated Media Incubation Center, And Specialized Vehicle Research And Development Center. It Is Not Only A Key Office Space For Enterprises To Carry Out Product Design And Research And Development Work, But Also Sets Up A Multimedia Cultural Exhibition Hall And A Product Display Area For Enterprises. Here, Through Carefully Planned And Designed Display Formats, The Many Characteristics Of The Product, Such As Features, Functions, Advantages, Can Be Presented To Visitors In All Aspects, While Also Effectively Conveying Important Information Such As Brand Value.

The Research Building Also Bears The Responsibility Of Building A National 400 After-sales Service Network And Providing Corresponding Technical And Service Support For This. As A Comprehensive Innovation Platform Focused On The Field Of Integrated Media, The Enterprise Integrated Media Incubation Center Can Provide A Series Of Comprehensive Incubation Services For Related Projects Or Teams, Covering Physical Space, Equipment And Facilities, Technical Support, Resource Docking, And Training Guidance.

Ask

What Is The Smart Factory Complex Building?

The Comprehensive Building Has A Construction Site Area Of 803.58 Square Meters, With A Total Construction Area Of 4875.18 Square Meters. It Presents A Six Story Above Ground Building Structure With No Underground Space.

The Building Includes Important Areas Such As Employee Cafeteria, Comprehensive Office Building, And Employee Rest Area. Among Them, The Comprehensive Office Building Is The Main Venue For Centralized Administrative, Management, And Business Work, While The Employee Cafeteria And Employee Rest Area Serve As Auxiliary Functional Areas, Providing Dining And Relaxation Places For Employees Respectively, Forming A Comprehensive Office Environment That Can Meet The Various Needs Of The Enterprise.

Ask

What Is The First Workshop Of The Smart Factory?

The Total Area Of Workshop 1 Is 38378 Square Meters. As A Final Assembly Workshop, It Has 9 Specialized Production Lines, Including Military Confidential Production Line, Standardized Assembly Line, Non-standard Vehicle Assembly Line, Road Maintenance Series Assembly Line, Logistics Support Assembly Line, Road Cleaning And Sweeping Assembly Line, Garbage Disposal Assembly Line, And Commuting And Living Assembly Line. This Diversified Workshop Configuration Enables Workshop 1 To Meet A Wide Range Of Production Needs, From Military To Civilian, From Standard To Non-standard, And Efficiently Complete Assembly Tasks.

The Workshop Is Equipped With Intelligent Warehousing Systems And Three-dimensional Warehouses, Which Not Only Improve The Space Utilization Of The Warehouse, But Also Achieve Automated Management And Rapid Allocation Of Materials. The Intelligent Warehousing System Can Monitor Inventory Status In Real Time, Ensuring The Timeliness And Accuracy Of Material Supply, And Providing Strong Logistical Support For The Continuous Operation Of The Production Line. The Workshop Material Transportation Adopts Advanced AGV Automatic Distribution System, Which Can Accurately And Quickly Distribute Materials To Various Workstations, Greatly Improving Material Circulation Efficiency And Reducing Manual Handling Costs And Time.

Ask

What Is The Second Workshop Of The Smart Factory?

The Second Machining Center And Welding Workshop Cover An Area Of 30240 Square Meters, Providing Ample Space To Accommodate Multiple Production Lines And Advanced Welding Equipment, Ensuring Smooth And Efficient Production Processes. There Are 8 Professional Production Lines In The Workshop, Including Automated Canning Production Line, Water Truck And Suction Welding Production Line, Compression Automation Welding Production Line, Compression Large Box Welding Production Line, Cutting Production Line, Accessory Welding Production Line, Washing And Sweeping Vehicle Welding Production Line, And Fire Welding Production Line. These Production Lines Cover A Wide Range Of Welding Needs And Can Meet The Welding Tasks Of Different Products.

The Automated Canning Production Line And Compression Automated Welding Line Extensively Use Automated Welding Equipment And Auxiliary Tooling Equipment, Which Improves The Accuracy And Efficiency Of Welding While Reducing Manual Operations And Labor Intensity. The Cutting Line Is Equipped With Advanced CNC Equipment Such As CNC Laser Cutting Machines, CNC Bending Machines, CNC Pipe Cutting Machines, And CNC Bending Machines. The Application Of These Devices Effectively Improves The Accuracy Of Material Processing And Production Capacity, Ensuring Product Quality. After All The Supporting Parts Are Welded, They Are Automatically Transported To The Feeding Point In The Painting Workshop Through RGV, And Then Automatically Transported To The Automatic Powder Spraying Line In Workshop 3 For Spraying. This Automated Logistics Transfer System Improves Transfer Efficiency, Reduces Losses And Time Delays During The Transfer Process.

The Workshop Cooperated With The Planned Launch Of The MES System For Production Control, Achieving Digital Management Of The Production Process. The MES System Can Monitor Production Progress In Real-time, Optimize Production Scheduling, Improve Production Efficiency, And Ensure Efficient Information Exchange Throughout The Entire Production System.

Ask

What Is The Third Workshop Of The Smart Factory?

The Third Automated Painting Center Covers An Area Of 17976 Square Meters. Adopting A Fully Automatic Stacking Conveyor System, It Can Automatically Identify Workpieces, Spray Accurately, Achieve Less Manual Operation, And Significantly Reduce Labor Requirements.

The Homework Process Achieves Complete Isolation Of People, Machines, And Materials, And The Production Environment Can Undergo A Qualitative Leap. By Adopting Powder Coating Technology Instead Of Paint Technology, The Emission Of Volatile Organic Compounds (VOCs) Is Greatly Reduced, Making The Coating Process More Environmentally Friendly. At The Same Time, It Can Promote The Process Of Green And Low-carbon Technology Transformation And Application In Enterprises, And Enhance The "green Content" Of High-quality Development Of Enterprises. The Painting Line Integrates Digital Coding Technology, Obtains Online Product Information Through Information Exchange With The Enterprise MES System, Associates Product Information With The Production Line Coding System, Automatically Generates Process Routes, And Guides The Automated Production Of Each Process Section Of The Product, Achieving Traceability Of The Entire Product Logistics Information.

The Relocation Of Smart Factories Is Imminent Now

Kaili Automobile Group Launches Large-scale Expansion Of Enrollment!

Multiple Types Of Job Openings

Welfare Is Even More Abundant!

Stop Recruiting When The Positions Are Full, Seize The Opportunity To Invest

-

The 'perpetual Motion Machine' Is Activated! Kaili After-sales Service Enables Customers T

2025-11-25

-

【 Zhuanqi News 】 It's Hot! Suizhou Intelligent Manufacturing Dominates The Screen In Beijing, A

2025-11-20

-

【 Overseas Recruitment 】 Kaili Automobile Group Overseas KD Factory Social Recruitment Notice!

2025-11-03