[Maintenance] Daily Maintenance Of Sprinkler Trucks

Hello, Welcome To Follow Kaili Automobile Group!

Nowadays, It Is Said That 'wolfberries Are Soaked In A Thermos Cup'. People Need Maintenance, And The Younger They Look, The Same Goes For Sprinkler Trucks. To Effectively Extend The Service Life Of Sprinkler Trucks, It Is Necessary To Pay Attention To Detailed Maintenance Of All Aspects Of The Sprinkler Truck. The Following Is A Daily Maintenance Learning Video For Our Sprinkler Truck, Which Includes The Maintenance And Upkeep Of The Chassis And Engine, As Well As The Installation.

Maintenance Of Chassis And Engine

Please Follow The Requirements Of The Car Chassis And Engine Manual For Maintenance.

1. Regularly Check The Sealing Of Components Such As Connectors, Switches, And Suction Hoses In The Waterway System. If Leakage Is Found, Repair Or Replace The Seals Immediately.

2. Regularly Check The Fixing Of The Water Tank, Pump Frame, And Bracket Of The Sprinkler Truck, And Tighten All Nuts To Ensure Reliable Connection.

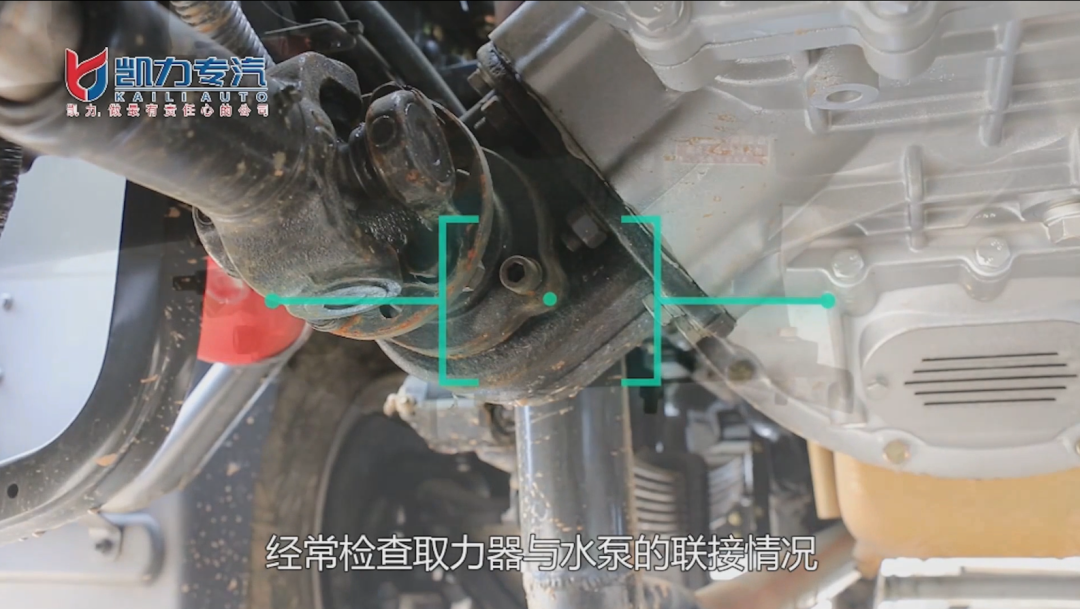

3. Regularly Check The Connection Between The Power Take-off And The Water Pump, Which Should Be Reliable And Operate Normally. If Oil Leakage Is Found Between The Power Take-off And The Water Pump During Use, The Seals Should Be Replaced.

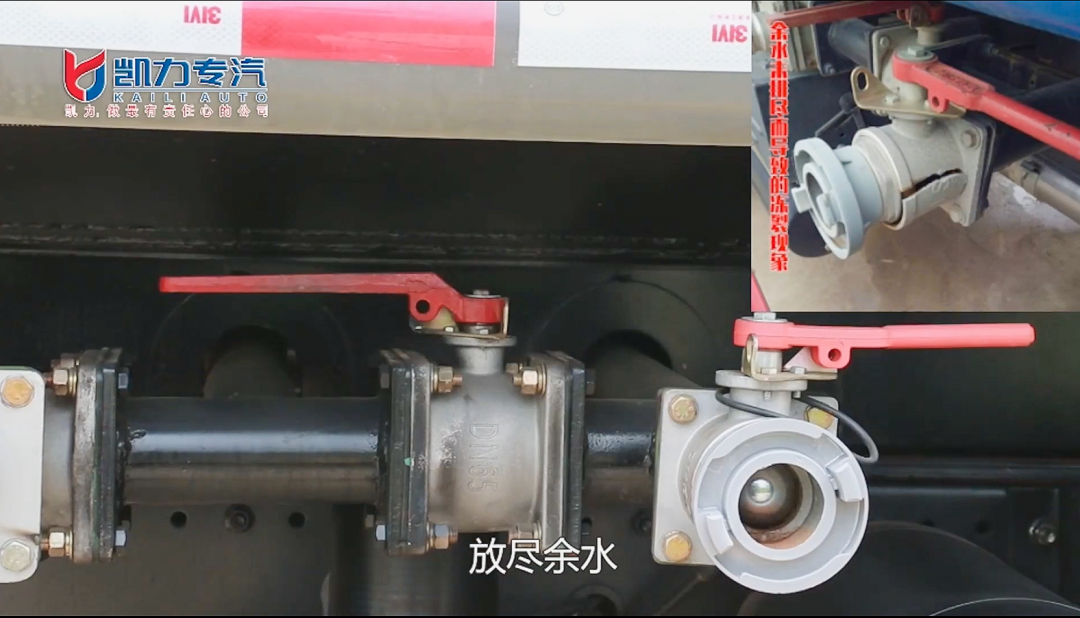

4. The Vehicle's Water System Does Not Have An Antifreeze Device. After Use In Cold Weather, The Remaining Water In The Water Pump, Water Tank, And Water System Should Be Immediately Drained To Prevent The Water Pump From Freezing And Cracking; At The Same Time, Open All The Working Ball Valves And Drain The Remaining Water To Prevent The Valves And Pipelines From Freezing And Cracking.

5. The Medium Through Which The Ball Valve Passes Should Not Be Too Dirty To Avoid Damaging The Sealing Ring And Reducing The Service Life Of The Ring Valve. Each Ball Valve Should Not Work In A Semi Open State For A Long Time, Otherwise It May Cause Deformation Of The Sealing Ring.

6. The Inlet Filter Screen Should Be Disassembled And Cleaned Regularly To Prevent Debris From Blocking The Filter Screen And Affecting The Pressure Of The Water Pump.

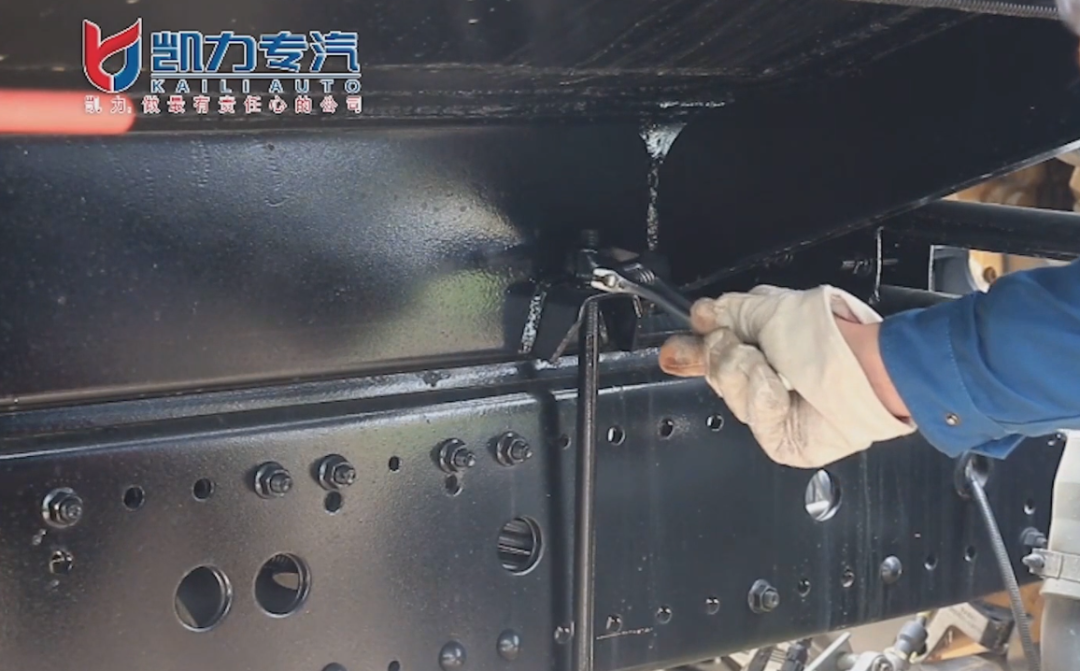

7. Due To The Wooden Rubber Pad Between The Tank Body And The Car Beam, The U-bolts Of The Water Tank May Loosen Due To The Deformation Of The Wooden Rubber After Being Loaded. It Is Necessary To Regularly Check And Adjust The Fastening.

8. When Pumping Water From An Outdoor Pond, It Is Important To Estimate The Depth Of The Water In The Pond. If The Water Source At The Suction Point Is Too Shallow, It May Be Necessary To Manually Dig Deeper Or Choose A Deeper Water Source. During Suction, It Is Important To Avoid Stones, Mud, And Other Debris From Entering The Water Pipe.

9. New Cars Should Avoid Using Emergency Braking, As This Can Impact The Braking System That Is Still In Running In, Increase The Impact Load On The Chassis And Engine, Damage The Tires, And Easily Leave Brake Marks On The Brake Discs. So It Is Best Not To Brake The Sprinkler Truck Urgently Within The First 300 Kilometers Of Driving. Of Course, This Is Under The Premise Of Ensuring Normal Safety. If There Are Any Uncontrollable Reasons In Practice, It Should Still Be Based On The Actual Situation.

10. Arrive At The Corresponding Service Station Of The Sprinkler Truck Chassis On Time For Initial Maintenance And Regular Upkeep. Late Or Early First Maintenance Is Not Advisable, As The Mileage Of The First Maintenance Is Calculated Through Scientific Experiments. Regular Inspections Can Better Maintain The Sprinkler Truck.